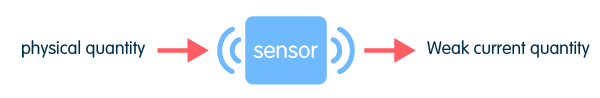

What is a sensor?

A sensor is a detection device that can sense the measured information and transform such information into electrical signals or other required forms of information outputs according to given rules to meet the requirements for information transmission, processing, storage, display, recording, and control. The mathematical expression of this process can be expressed as follows:

Classification of sensors

Can this data acquisition device measure a pressure sensor? This is a question that is often asked. To answer this question, we must first learn about the classification of sensors. There are many ways to classify sensors. Since users focus on what they specialize in, sensors are usually classified based on the type of measured physical quantity, such as pressure sensor, temperature sensor, humidity sensor, displacement sensor, acceleration sensor, and so on. However, it is not convenient for selecting a data acquisition device by using this classification method. When selecting such a device, you need to pay attention to the output type of the sensor. Based on the type of data output, sensors can be classified as follows: voltage type, current type, resistance type, capacitance type, frequency type, pulse type, and encoder type, among others.

Standard voltage sensor/transmitter

Sensors have many output types. Among these types, the standard voltage sensor/transmitter is the most common and convenient one to connect the data acquisition device for data acquisition. The output voltage of this sensor generally ranges from 1 to 5V, 0 to 5V, 0 to 10V, ±5V, or ±10V. Most acquisition devices have a range of 10V or 5V, which allows its direct acquisition and effective use of the entire range.

The output voltage of some sensors differs little from 5V or 10V, although it is not equal to such value. For example, a humidity sensor has an output voltage of 0 to 3V but no acquisition device with a range of 3V. In this case, we can also use the range of 5V for acquisition. Despite any range loss, the degree of such loss is acceptable. So, if the output voltage of one sensor is 1V and a senor having a range of 5V is used for acquisition, will such a range loss be acceptable? We can calculate it roughly. If a 16-bit acquisition device having a range of 5V is used to acquire the sensor with an output range of 1V, four-fifths of the range will be lost and the volume of acquisition will be less than 14 bits. To address this problem, the best way is to use an acquisition device with a range of 1V or an acquisition cad with a range close to 1V.

It can be seen that a data acquisition device can offer a larger range, which is quite helpful for the data acquisition of sensors with different output ranges. For this reason, Smacq’s USB-3000 series data acquisition devices provide users with a variety of range options, namely 10V, 5V, 2.5V, 1.25V, and 0.64V. Meanwhile, each analog input channel can use different ranges in the same data acquisition. This provides convenience for the integration of multiple sensors in the same data acquisition device.

Some sensors range little in the output voltage, only a few mV or dozens of mV. For instance, the output of most weighing sensors is 2mV/V. When driven by a 10kV power supply, it only has a full range output of 20mV. In this case, there are generally two choices. One is to use a special weighing data acquisition device. Anyhow, this type of data acquisition device is poor in universality, so it is not convenient for the device to be integrated with other sensors. The other is to use a signal conditioning circuit/module, which can be simply understood as amplifying the signal to 5V or 10V, and then to a universal data acquisition device for acquisition. Generally, this signal conditioning circuit is called a transmitter.

Sensor for current signal output

There is also a large category of sensors/transmitters that have a current output. To acquire data by using these sensors/transmitters, current signals must first be converted into voltage signals. For data acquisition of current signals, please refer to Smacq’s another document titled Collection of Current Data with Data Acquisition Device.

Acquisition of frequency, pulse, and encoder signals

Acquisition of other signals

Schematic diagram of the signal link passing through the transmitter

The connection between the sensor and the acquisition device

Many types of signals cannot be directly connected to the universal data acquisition device, such as the weighing sensor mentioned above. Thermocouples for temperature measurement and sensors with resistance output (PT100, etc.) also output small signals. To connect these sensors to the universal data acquisition device, it is necessary to convert signals into standard voltage signals through the transmitter and then acquire the signals of the transmitter through the acquisition device.

This section mainly describes the connection between the standard voltage output sensor/transmitter and the acquisition device. For other types of sensors, please refer to relevant documents or contact Smacq for technical support. Most sensors/transmitters have three or four connecting wires, which are power supply positive, power supply negative (power supply grounding), signal output, and signal negative (signal grounding). We should select a power supply for the sensor according to the requirements of the sensor manual, and then connect it to the acquisition device, as shown in the figure below.

Schematic diagram of the connection between the sensor and the acquisition device

Two aspects need to be highlighted about this connection diagram. First, the power supply negative and signal negative of some sensors with three connecting wires share the same wire, so it is necessary to connect this wire to the negative (grounding) terminal of the power supply and the AI Sense of the acquisition device at the same time. Second, the sensor is generally powered by a switching power supply. The negative output terminal of most switch power supplies is not connected to the ground. In this way, the sensor is a floating source for the acquisition device, so AI Sense and AGND need to be connected together through conductors. If it is determined that the acquisition device and sensor are grounded together, it is unnecessary to connect AI Sense and AGND together with wires. For connection problems related to the floating source and the grounding source, please refer to the relevant contents in the USB-3000 series user manual.

Data acquisition software

To allow users to obtain data quickly, Smacq offers users the Smacq DAQ Software, in which users can start data through simple configuration. The software provides the function of unit conversion, which can be directly displayed in the unit of the measured physical quantity. The data acquired at the same time can be stored, played back, and saved in CSV format. For more information about the software, please refer to the Quick Use Guide of Smacq DAQ Software.